Composite materials

The utilization of structural components and sub-assemblies in pre-impregnated high-performance composite materials is REXIAA’s core business and primary skill.

The weight / volume / resistance of composite materials offers efficient and innovative answers for the needs of the aeronautics and land transport sector.

We convert glass, carbon and Kevlar fibres, hybrid materials, structural foams, etc. We provide the most appropriate technological solution for your requirements and the volumes to be produced.

The utilization of structural components and sub-assemblies in pre-impregnated high-performance composite materials is REXIAA’s core business and primary skill.

The weight / volume / resistance of composite materials offers efficient and innovative answers for the needs of the aeronautics and land transport sector.

We convert glass, carbon and Kevlar fibres, hybrid materials, structural foams, etc. We provide the most appropriate technological solution for your requirements and the volumes to be produced.

Technologies

We continually invest in advanced technologies for the utilization of composites.

Pre-impregnated composite material technology enables us to produce efficient and reliable components and honeycomb or foam sandwich structures.

Mould bottom finishing technology, utilized since 2011, applies a coat of primer immediately after moulding. We thereby improve quality to offer you a perfect finish.

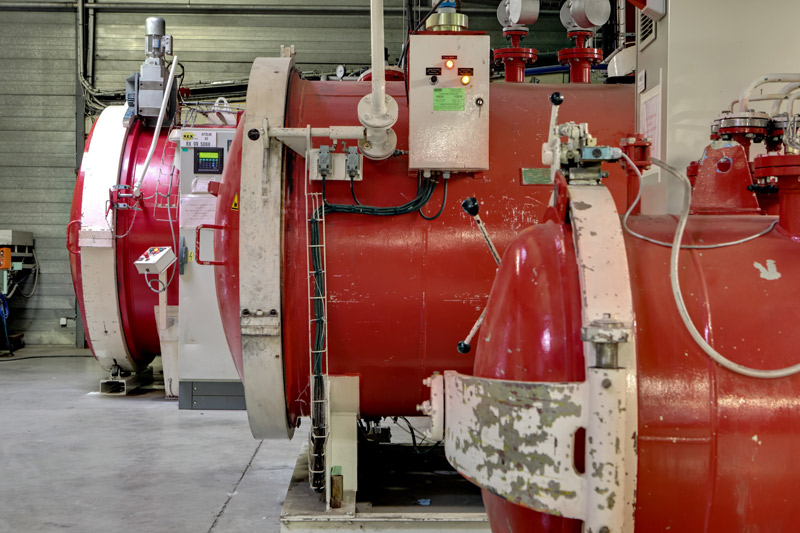

Automated fabric cutting, laser positioning, high-capacity autoclaves and “out or autoclave” technology are all benefits we provide for our customers. Our pool of machinery enables us, in particular, to handle the production of large sub-assembles.

We continually invest in advanced technologies for the utilization of composites.

Pre-impregnated composite material technology enables us to produce efficient and reliable components and honeycomb or foam sandwich structures.

Mould bottom finishing technology, utilized since 2011, applies a coat of primer immediately after moulding. We thereby improve quality to offer you a perfect finish.

Automated fabric cutting, laser positioning, high-capacity autoclaves and “out or autoclave” technology are all benefits we provide for our customers. Our pool of machinery enables us, in particular, to handle the production of large sub-assembles.

Resources

4°C to - 18°C cold storage rooms.

Automated fabric cutting (Gerber technology with unwinding machine and ink jet marking).

5-axis CNC water jet cutting.

Fibre placement optimization (CutWorks, FiberSIM software).

LPT and SL laser positioning.

Air conditioned wrapping rooms with temperature and humidity control.

Air conditioned bonding rooms.

Large capacity autoclaves.

Presses with heating plates.

Ovens.

3 and 5-axis CNC machining for soft and hard materials.

Non-destructive ultrasonic testing.

4°C to - 18°C cold storage rooms.

Automated fabric cutting (Gerber technology with unwinding machine and ink jet marking).

5-axis CNC water jet cutting.

Fibre placement optimization (CutWorks, FiberSIM software).

LPT and SL laser positioning.

Air conditioned wrapping rooms with temperature and humidity control.

Air conditioned bonding rooms.

Large capacity autoclaves.

Presses with heating plates.

Ovens.

3 and 5-axis CNC machining for soft and hard materials.

Non-destructive ultrasonic testing.

Copyright © 2014 All rights reserved. - Legal information